This is a simple project, but one I've been meaning to do for a few months now.

Apart from the beautiful charcoal coloured Victorian fireplace, the colour scheme in our bedroom is very neutral. The walls are painted in light grey and there's a cream carpet left over from the previous owners - I haven't helped much by adding soft grey bed linen and white lacquer drawers!

To add some personality and a focal point to the room I've hung one of my mum's brightly coloured paintings of Saint Tropez over the charcoal Victorian fireplace. These cushions add a bold touch against the plain bed linen and the warm wood of the bed frame, although I think I could have been more adventurous by adding a punchy magenta piping or pompom trim! The ceiling lampshade is made from some beautiful silver crushed velvet (in Voyage Mimosa - £30 a metre from John Lewis) and I made sure that I bought extra at the time so that I could incorporate it into some other soft furnishings in the bedroom.

I finally tackled an invisible zip closure rather than my lazy pillow case fold...well I was forced into doing this or otherwise I didn't have enough silver velvet to back all three cushions! But I'm pleased that I did as they give a much more professional finish to my cushions. I also reused some feather cushion inserts rather than the cheap polyester ones and they make such a difference to the way the cushions look and feel.

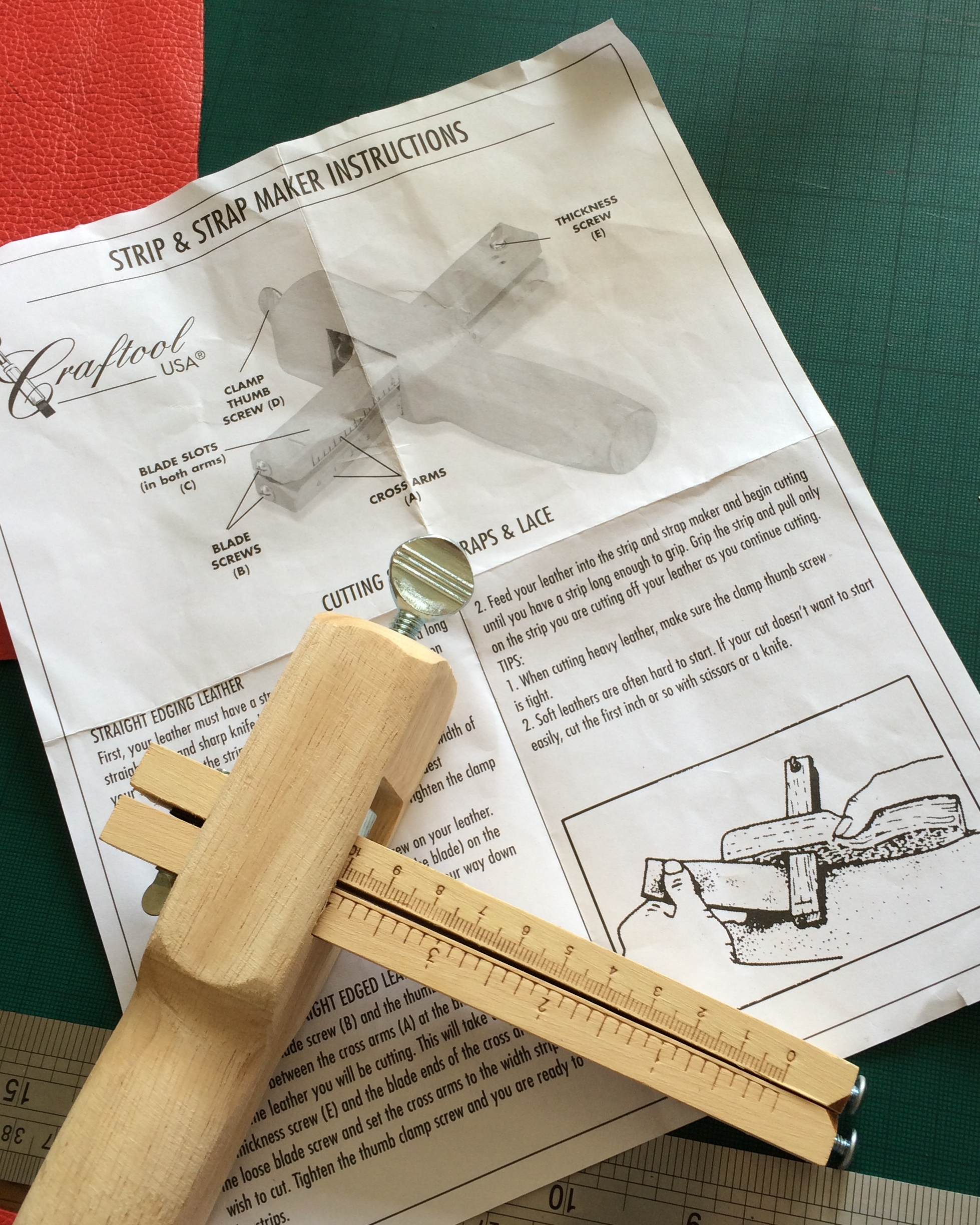

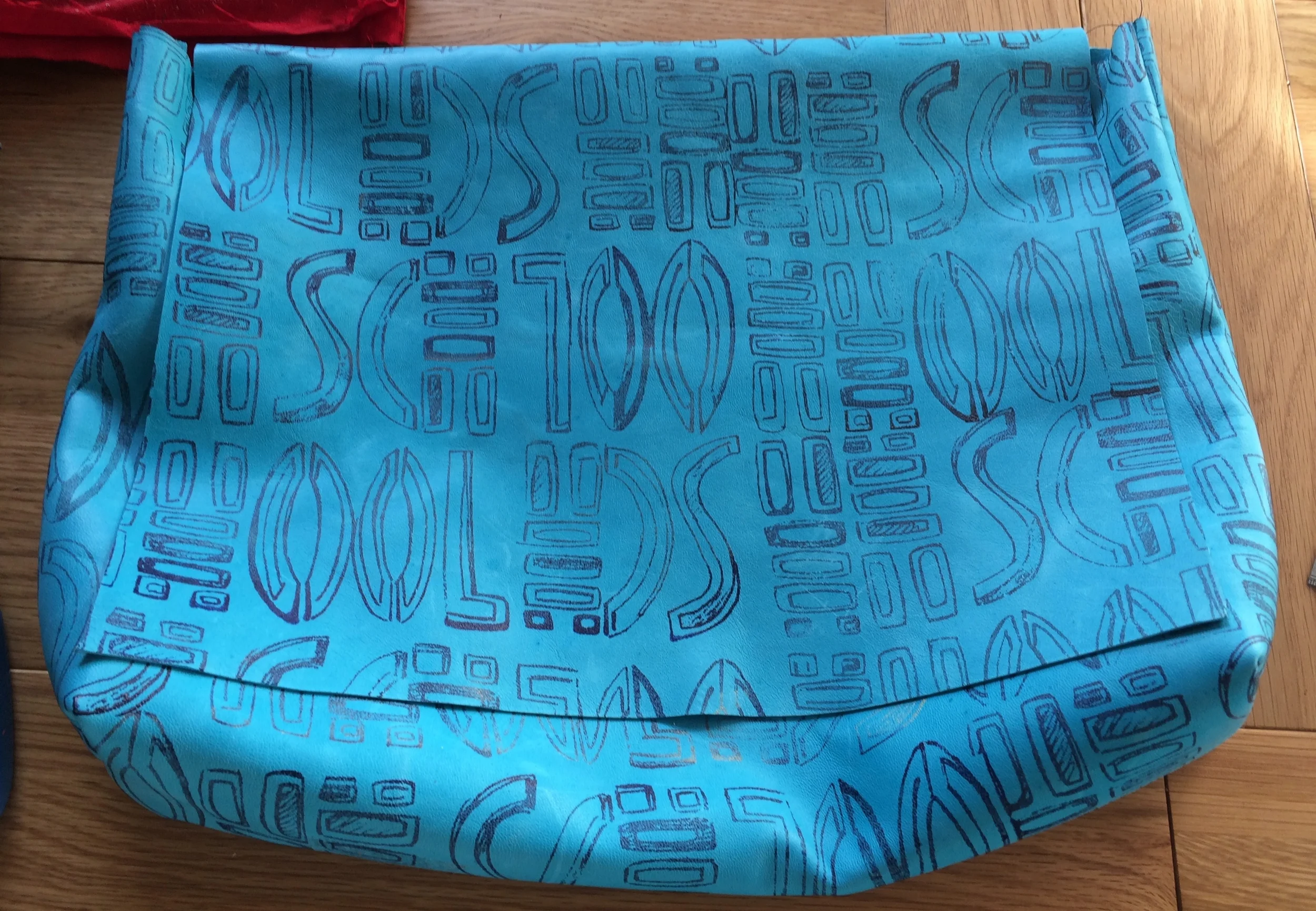

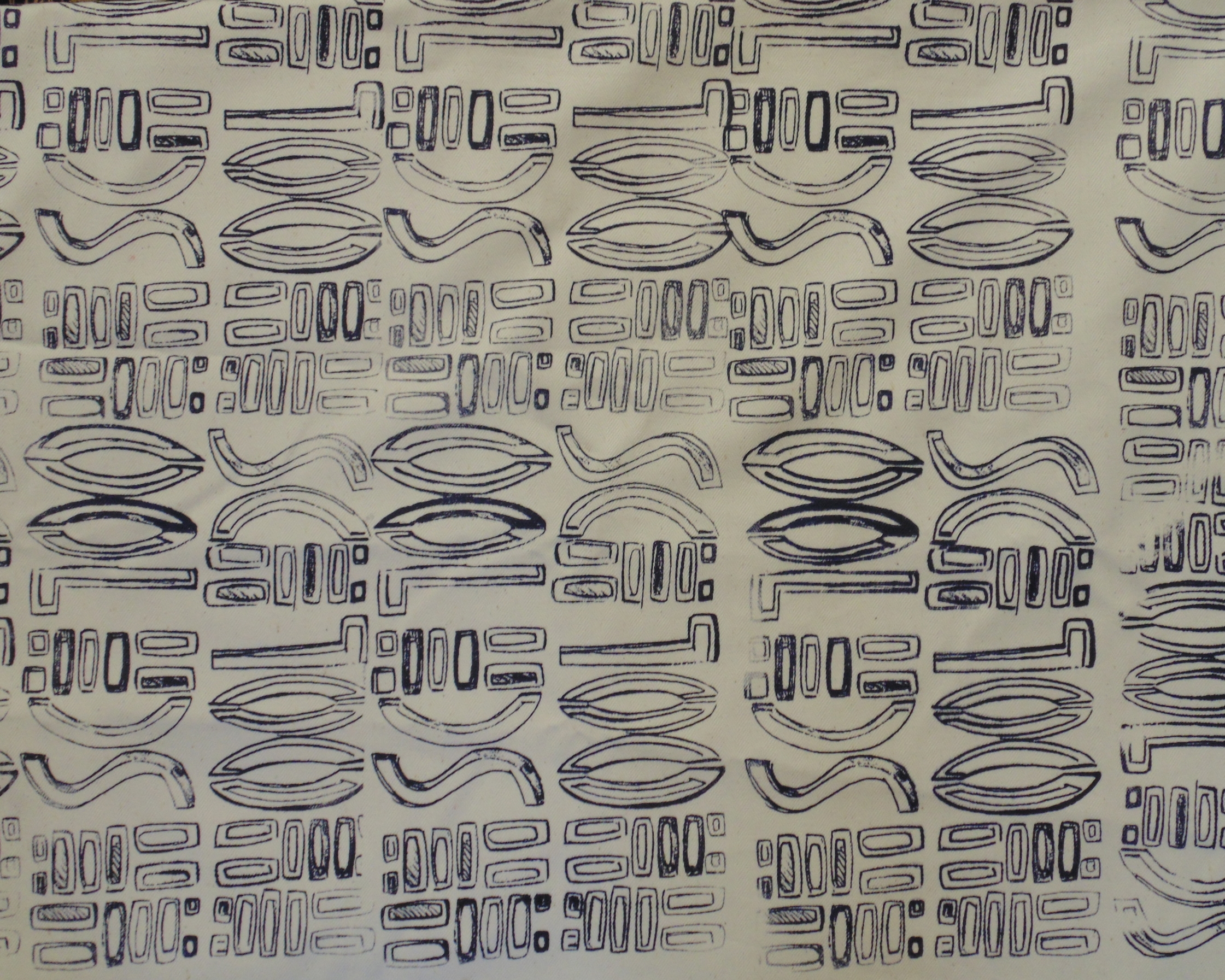

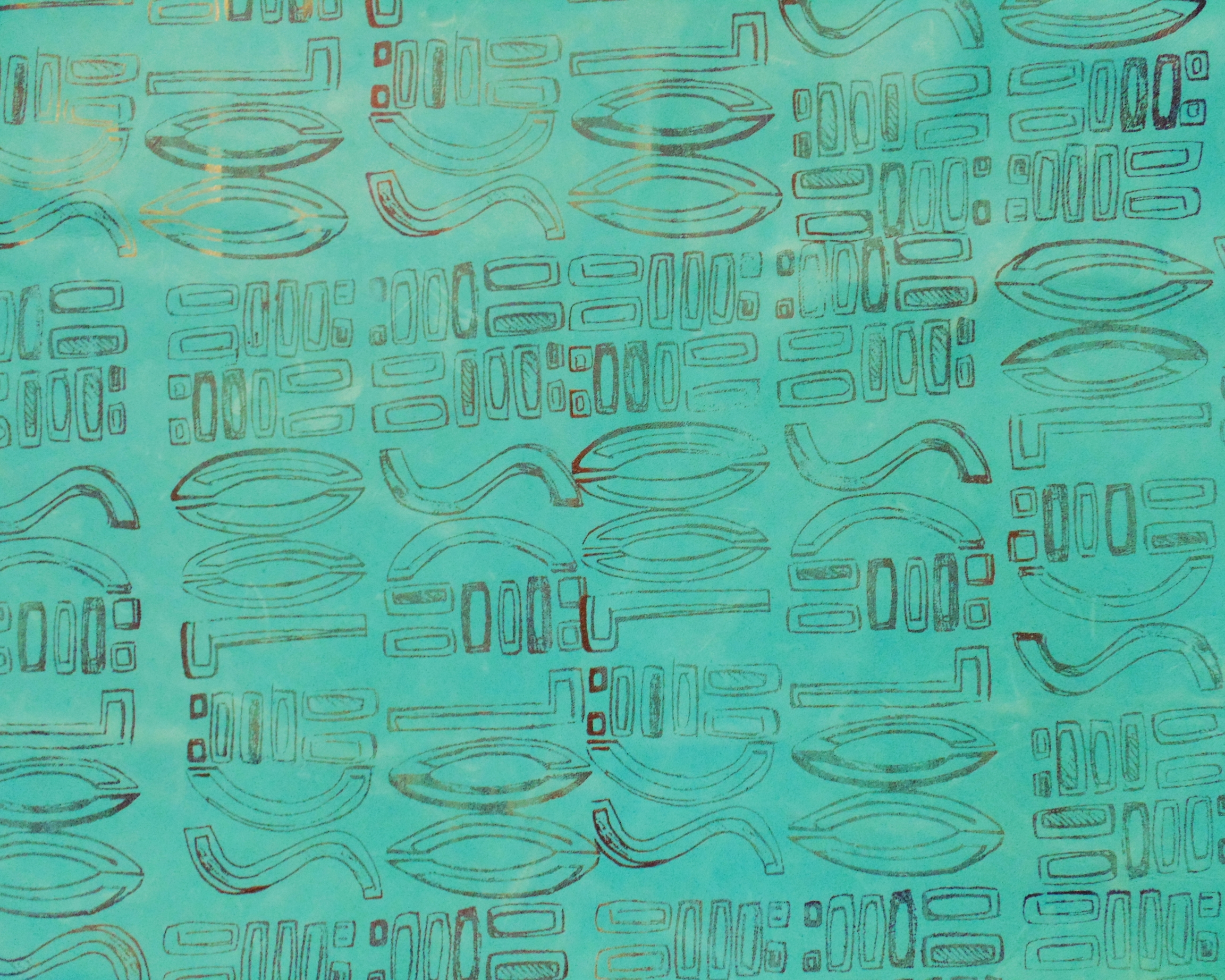

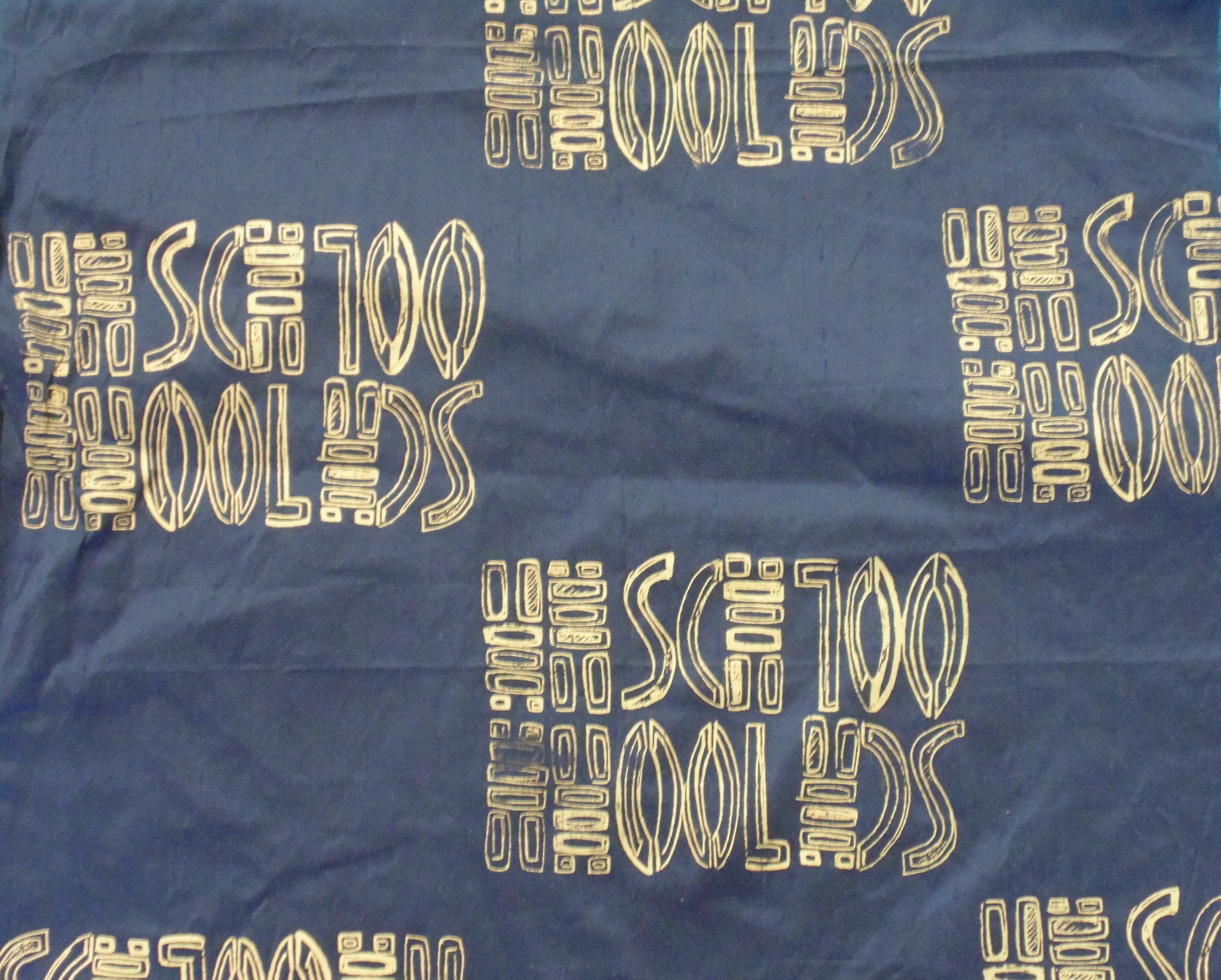

I used two different fabrics for the front side of the cushions. The square cushion is made from a square remnant of a Designers Guild fabric (that I picked up for £1!) and the rectangular cushions I printed myself using my Rennie Mackintosh inspired screen print design on some navy silk taffeta.

It was tricky to get the pictures right as there is so much sunlight streaming into the bedroom that most of my photos end up overexposed! That said, I'm very pleased with the results of the individual cushions and overall improvement to the whole room :)

My furry little model Winston! This was the only shot where he stayed still long enough for me to take the photo...shame that you can't really see the cushions.